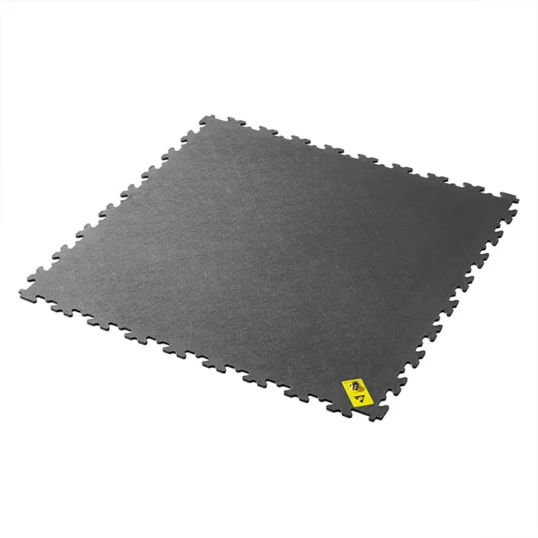

X500 X-Joint ESD Flooring System

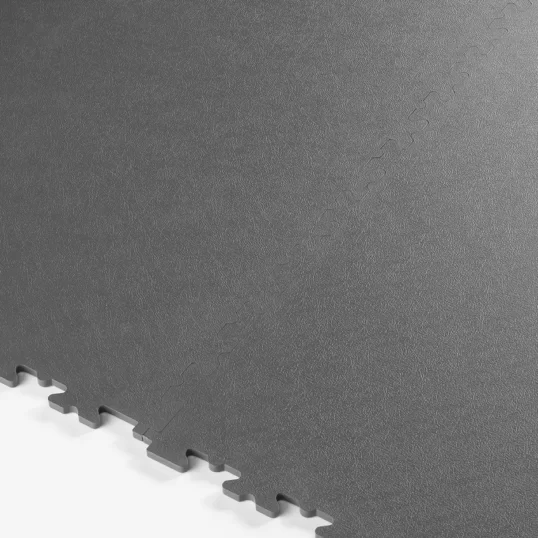

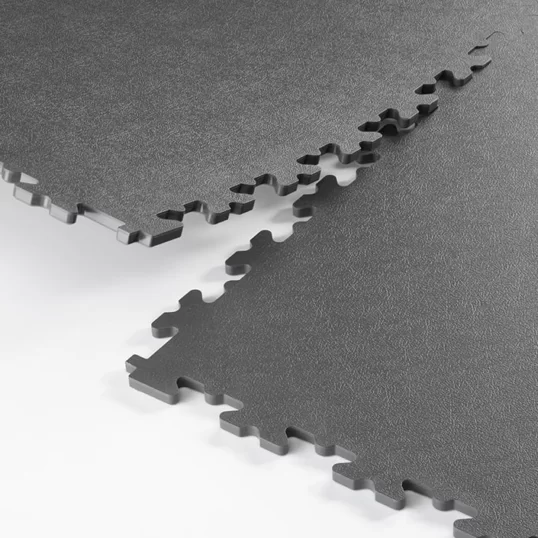

Manufactured by us in the UK, the X500 static dissipative tile offers a distinct design with an X-Joint connection and lightly textured finish. Tested to industry standards, it’s the most reliable and effective ESD solution available. Get a quote today, or visit our online shop and choose from 5mm or 7mm thicknesses or our anti-fatigue version.

Colours

Specifications

Perfect for

Installation

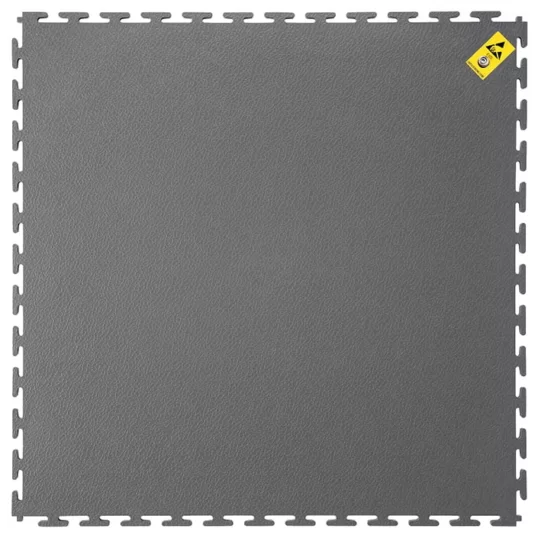

E500 Original ESD Floor Tile

Just like the X500, the E500 7mm thick ESD flooring system is a completely modular static control solution. Simply lay tiles with an ESD grounding kit to control static discharge and protect sensitive electronic devices from damage, data loss or complete failure.

Colours

Specifications

Perfect for

Installation

Why businesses trust Ecotile’s ESD flooring

ESD flooring is essential for environments where electrostatic discharge could harm electronic devices, people and flammable materials.

Ecotile’s ESD interlocking floor tiles provide a hassle-free dissipative flooring solution to protect microelectronics, sensitive devices and explosives from static.

That’s why they’re the trusted ESD choice for 1000s of leading businesses worldwide, including Siemens, Toyota and the UK’s Ministry of Defence.

With over 25 years experience in anti-static flooring solutions, Ecotile is renowned worldwide. Request a free no-obligation quote, buy our interlocking ESD tiles online, or purchase through one of our trusted resale partners. Whether you’re installing the floor yourself or using our expert team, we’re here to help.

Benefits of Ecotile ESD interlocking floor tiles

Whether you’re looking to replace a failed or worn anti-static floor, or need to create a new Electrostatic Protected Area, Ecotile can be integrated into your static-controlled area without fuss. Benefits include:

- Lifetime guarantee of ESD performance

- No disruption or downtime during installation

- Can be lifted quickly (ideal for leased/temporary spaces)

- Easily replace individual tiles if damage occurs to restore compliance

- Completely reusable, so you’ll never lose your initial investment

- No adhesives, special floor prep or moisture protection required

- Installable over almost any subfloor

- End-to-end solution (including installation, testing and certification)

- Made in Britain

- 10 year warranty

Ecotile has over 25 years of experience in manufacturing and installing ESD floors in a range of environments. These include electronics manufacturing facilities, SMT circuit assembly areas, cleanrooms, laboratories, data centres, hospitals, pharmaceutical factories, and explosive ammunitions facilities. We’re also the trusted ESD solution experts for the MoD. We’ve worked with the MoD Defence Ordnance Safety Group to create a bespoke conductive floor tile to meet their regime standards.

How does Ecotile ESD flooring work?

Engineered to safely discharge static-build-up, each PVC interlocking floor tile contains a controlled amount of stainless-steel microfibres. These microfibres act like conductive veins, providing a path for static to travel through the floor surface and dissipate safely to ground.

To ground the floor, a tile with a metal stud is installed every 60m2 and connected to an earthing point (usually via a standard 3-pin bonding plug). This allows static to complete its circuit and flow safely to ground. To unify conductivity, Ecotile ESD modular floor tiles are installed over a grid of conductive tape laid on the subfloor.

Thanks to this process, Ecotile’s ESD tiles never wear down or lose their static dissipative properties over time. You won’t need to worry about static damage from the moment our solution is installed.

ESD floor testing & certification

It is critical that your floor meets industry specific standards and falls within the agreed electrical resistance range after it has been installed. Our tiles have been independently tested against EN 14041:2018, the European Standard for Essential Characteristics of Resilient, Textile, Laminate and Modular Multilayer Floor Coverings. This verifies their performance and ensures that our tiles meet critical health, safety and environmental criteria.

Our ESD tiles have also been tested to meet the following international standards:

- BS EN 61340-5-1 Edition 2 2016-05 – Electrostatics. Protection of electronic devices from electrostatic phenomena

- IEC 61340-5-1 Edition 2 2016-05 – Electrostatics. Protection of electronic devices from electrostatic phenomena

- Human Body Model (HBM) Testing & EN / IEC 61000-4-2 Edition 2 2016-05 2008.

- ANSI/ESD S20.20-2014 & ESD STM97.1-2015

- BS EN 1081:2018+A1:2020 – Resilient floor coverings. Determination of electrical resistance

- MOD DSA03. OME Part2 (JSP482) & US MIL-STD-1686

We can test your new floor against the standard of your application and provide you with a written certification of compliance for your operational records. An ongoing test schedule can also be implemented. As per BS EN 61340 Guidebook recommendations, Ecotile can test your floor annually or as frequently as you require for your peace of mind.

Full support and recommendations for after-care are provided, ensuring a suitable floor cleaning routine is implemented.

Get a free quote today

Get the ESD protection you need with Ecotile. For further information on our anti-static ESD flooring systems please contact us. We offer a complete supply and installation service or you can shop online with fast delivery. We also supply conductive grounding tape, earth bonding plugs, studded ground tiles, ramp sections in various colours, and anti-fatique ESD tiles.